3 Mistakes to Avoid When Ordering Custom Jacket Embroidery in Orlando

Many people assume jacket embroidery is straightforward, but the reality is that design, material, and planning decisions determine whether the final jacket looks polished or problematic. Understanding common mistakes when ordering custom embroidery can help you avoid costly errors and ensure your jackets look professional, durable, and well-crafted.

Ordering Custom Jacket Embroidery in Orlando is not just a simple purchase. It is a responsibility. Whether you are creating jackets for your business, team, school, or event, the final product represents your brand, identity, or message. A poorly executed embroidered jacket can damage credibility, waste money, and create long-term disappointment.

So knowing what not to do is very important. To help you ace the jacket embroidery game, we are here with this blog. It will guide you on the mistakes that you should be mindful of at all times.

What To Avoid When Ordering Custom Jacket Embroidery In Orlando

Below are the most common mistakes to avoid when ordering custom embroidered jackets.

1. Design & Artwork Mistakes

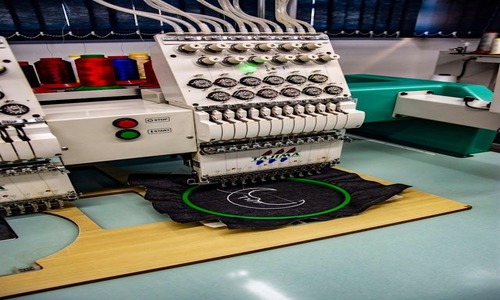

Design quality directly affects how well embroidery turns out. Poor artwork leads to distorted logos, unreadable text, and wasted production time.

Overcomplicating Designs

One of the most common mistakes people make with custom jacket embroidery is choosing overly detailed designs. While intricate logos may look impressive on a screen, embroidery has physical limitations. Small text, thin lines, gradients, and excessive details can blur or merge when stitched.

Simple, bold designs translate far better into embroidery. Clean lines, strong shapes, and limited text ensure the logo remains readable and visually appealing even from a distance. When in doubt, simplify your artwork before production.

Poor File Quality

Low-resolution files are a major reason embroidery projects fail. Submitting pixelated images or screenshots often leads to unclear stitching and distorted logos.

For best results, always provide high-resolution vector files such as AI, EPS, or PDF formats. These files allow embroidery digitizers to accurately map stitches, ensuring sharp outlines and consistent results, especially important for custom embroidered jackets intended for professional use.

Ignoring Color Accuracy

Another overlooked mistake is assuming that colors will look the same on fabric as they do on a screen. Digital designs use RGB colors, while embroidery threads follow Pantone systems.

What looks bright on a monitor may appear darker or muted once stitched. Always review thread color charts and approve final color selections before production begins, especially for brand logos where color consistency matters.

Bad Placement

Placement errors can ruin an otherwise great design. Embroidering over seams, zippers, pockets, or thick cord lines often causes puckering, distortion, and uneven stitching.

For example, attempting custom embroidered jackets front and back without proper spacing can result in awkward alignment. Always confirm placement dimensions and avoid structurally complex areas of the jacket to maintain a clean finish.

2. Material & Production Mistakes

Fabric choice, stabilizers, and thread selection determine whether embroidery looks smooth or puckered. Thin, stretchy, or unstable fabrics are more likely to distort under stitching tension.

Using the wrong thread can cause long-term issues like warping, fading, or thread breakage, which will directly impact the question, “How much does it cost to get a jacket embroidered?” as rework, material replacement, and quality fixes can significantly increase the final price.

Wrong Fabric Choice

Not all jackets are embroidery-friendly. Thin or stretchy fabrics tend to shift during stitching, leading to puckering and warping.

Fabrics like lightweight polyester, spandex blends, nylon windbreakers, and thin fleece require special handling. If the fabric is not suitable, even high-quality stitching will not look right. Always confirm that your jacket’s custom embroidery is ideal for the jacket’s fabric.

Poor Thread Selection

Thread quality matters more than most people realize. Cotton threads absorb moisture and fade quickly, while metallic threads can break easily and lose shine over time.

High-quality polyester embroidery threads are usually the best choice for jackets. They are durable, colorfast, and withstand washing, weather, and daily wear, making them ideal for professional jackets. So choose wisely.

3. Process & Planning Mistakes

Skipping samples, underestimating timelines, or failing to proof final designs are common causes of embroidery errors. Without proper planning, mistakes often go unnoticed until production is complete. This may result in rework, delays, and extra costs.

Research states that sample testing reduces production errors by up to 85% and can save businesses an average of 30% on restitching and replacement costs by catching issues early in custom projects.

Skipping Samples

Skipping a sample is one of the most expensive mistakes you can make. Without a physical sample or a detailed digital mockup, issues like incorrect sizing, poor color contrast, or misplacement often go unnoticed until the entire batch is complete.

If you are searching for custom jacket embroidery near me and working with a new provider, then always request a sample before placing bulk orders.

Underestimating Time & Budget

Many customers underestimate how long embroidery takes. Design digitization, approvals, stitching time, and quality checks all add to the timeline.

Budget mistakes also happen when customers don’t account for design complexity, stitch count, placement, and turnaround time. Rushed orders and complex designs usually increase costs.

No Proofreading

Misspelled names, incorrect sizing, or wrong color choices are surprisingly common. Once embroidery begins, errors cannot be undone. Therefore, if you have not double-checked spellings, measurements, and layout before production starts, then even a small oversight can be disastrous. It will turn into a costly mistake that cannot be corrected once the embroidery process begins.

4. Knowledge Gaps That Lead to Mistakes

Many mistakes occur because customers assume embroidery works like screen printing. Knowing embroidery limitations helps you communicate better with providers and avoid unrealistic expectations. If you are planning to find custom embroidered jackets near me for business purposes, then it is better to get knowledge about embroidery beforehand. This will help you convey your requirements constructively.

Final Word

Custom jacket embroidery requires careful planning, attention to detail, and the right production partner. Small mistakes may seem minor at first, but they can quickly turn into major disasters, especially when placing bulk orders. Once embroidery begins, errors are often permanent, leaving you with ruined jackets, wasted inventory, and unexpected costs.

If you want reliable results without the risk, MJ Printing & Embroidery is a dependable choice for businesses and individuals seeking Custom Jacket Embroidery in Orlando. With expert guidance, quality materials, and thorough processes, MJ Printing & Embroidery helps turn your ideas into flawless embroidered jackets, done right the first time.